WHY INVEST IN STELLARIA?

Because we have taken the right choices, the STELLARIUM design is in advance versus the initial planning, with unique features on the market:

- 100 % renewing its fuels = multi-recycling WPR fuels, and fully closing the fuels cycle, fully symbiotic with existing WPR's fleets.

- Can burn multiple types of fuels U, Pu, Th

- 20 years of salt autonomy

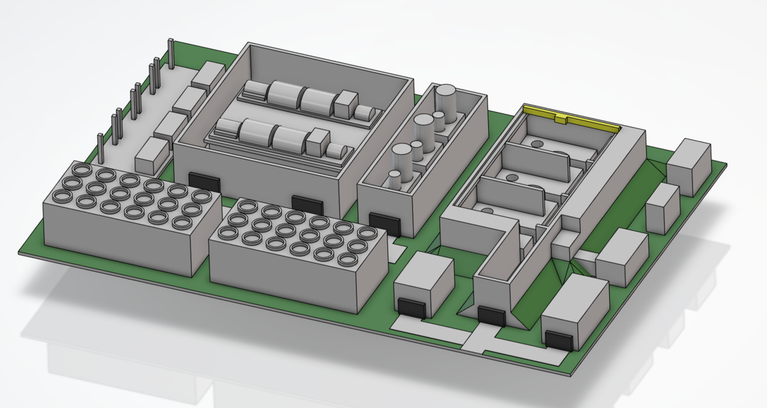

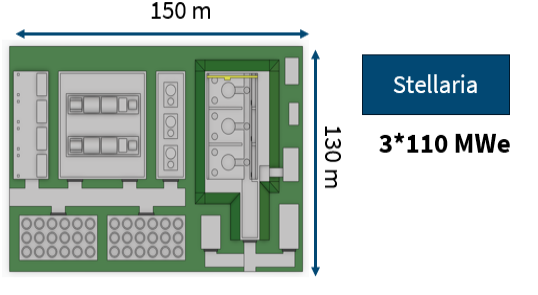

- Very simple design for lower CAPEX and basic operating

- No ESPN no pressure for most of the reactor to reduce costs.

- Scalable modular CAPEX to adapt to any power levels : easy to scale up or upgrade power levels of a site

- Very fast power ramp-up's : stop & go, -+70% of nominal power per minute, at least as fast as gas.

- Passive coolant (NaCl based)

- Passive heat evacuation after any stop

- No exclusion safety zone (EPZ) unlike all classic reactors

- Never any excess of fissile fuel incore by design = safety while operating

- Can burn americium waste : reducing decay time from 300 000 years to 300 years, dividing by 3 the size of deep storage for long life waste.

- Vessels can be changed for continuous optimization and for longer life of installation (unlike WPR's)

- Fully circular installation : all inside components can be changed.

- Reduced risks by reusing all the REX of existing nuclear installations: we only use our core innovation, fast neutronic molten salt features, to its full power.

- Can store up to 20 TWh in one single reactor salt. This pile cans store around 70 Millions times more energy by liter than any IO-Lithium Battery

- We already have 5 STELLARIUM's pre-orders from worlwide customers

Nuclear specialists

STELLARIA is partner of the CEA, and ORANO to fully design the nuclear area. The nuclear installation will be mostly underground, reducing the nuclear safety zone (DPZ) to a diameter of a few dozen meters.

Nuclear industrial partners will design the auxilliaries, the heat exchangers as well of the steam generators, as much as possible off the self.

Off the shelf turbines

Turbines specialist will provide their expertise to create a modular house to host the steam turbine, so as to convert heat into electrical power with proven and off-the-shelf solutions

The turnkey modular solution

Our Engineering Procurement and Contractor (EPC) partner will design the fully modularized installation thansk to is great return of experience from other sectors, like the Oil & Gas or the Mining segment. Modules will be produced and tested in yards and factories, then disassembled, and then reassembled onsite for final testing. We will ensure ,as an industrial team, a modular installation, sclabale and replicable, up and running, in less than 36 months.

The best power control system

Electrical distribution specialists will design the digital twin, connected to the energy monitoring and control system that will transform industrial sites into prosumers (producers/ consumers). They will also manage "the last mile" to distribute the 24/7 power towards customers' grids

100 Billion €

The energy bill of electro-intensive sites in Europe

The SMR european market will represent 30 Billion Euros per year by 2040.

STELLARIA aims to produce 30 modules per year in series by 2037 for Europe and will extend the sales towards Middle East and South-East Asia.

Our target price of a gen 4 molten salt SMR is as low 50 € per MWh, unleashing the full potential on fast breeders at a competitive cost against gas power plants. As it is ultra flexible on demand power, it is a perfect complement of large disptachable power plants.

Out target ROI for a STELLARIA SMR versus a gas power plant that needs 250 MW of gas per year at 50 € /MWh, is 3 years.

3 main investment phases

The green impact of your investment is maximal. We provide one of the most advanced climate technology, off-setting CO2 at the scale of the biggest industrial sites in the world.

- Net-negative in waste production, no CO2, and minimal amount of metallic resources per KWh.

- Decarbonized compact & safe on-demand power, anywhere, anytime.

STEP 1 DESIGNING

2023-2026

We get benefits of France 2030 to achieve our design stage in 4 years, 2 years for basic design and 2 more years for the detailed design.

The end of this phase will be the achievement of "the authorization to build" the first breeding molten salt pile ever built in the world.

STEP 2 PROTOTYPING

2027-2031

We will design our prototype as a the first european fast neutron molten salt reactor research facility in the world, generating the first revenues for the company. This proofpoint of a functional prototype will the the best asset to justify investments in a gigafactory and launch the business.

STEP 3 MANUFACTURING

2031-2036

A gigafatory of molten salt piles will be created to drastically reduce the cost per module.

Large industrial investors will take over this phase to build a large manufacturing facility that will be able to produce the capacity of 100 modules per year and will export the technology around the world.

Nous avons besoin de votre consentement pour charger les traductions

Nous utilisons un service tiers pour traduire le contenu du site web qui peut collecter des données sur votre activité. Veuillez prendre connaissance des détails et accepter le service pour visualiser les traductions.